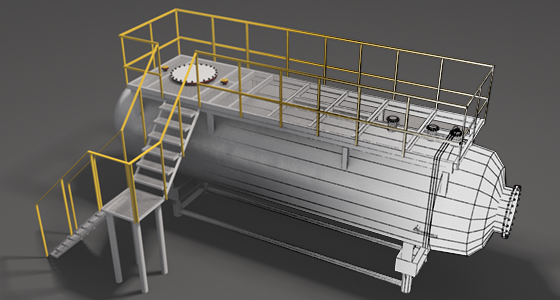

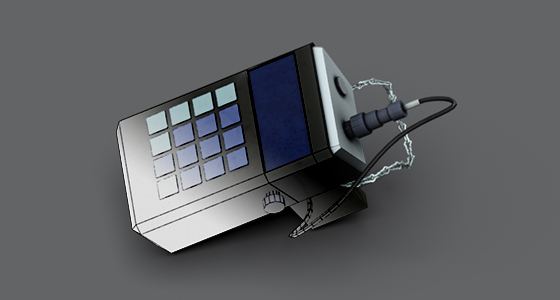

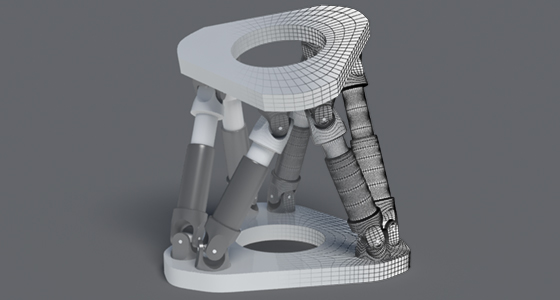

3D Modelling of Technical Objects

We develop high-quality 3D models of various technical objects to display it in real-time for games or professional applications.

The Computer Modelling Laboratory allows for the following 3D models:

- Basic models with an average of 10 000 - 15 000 polygons, and 2 LOD models containing approximately 3000 and 1000 polygons;

- Models which do not contain isolated points;

- Models which do not contain polygons that are on the same plane with "holes" between the ribs, hidden polygons, tops, and edges;

- According to the drawings of the prototype (appearance of model is close to real photos of a prototype and it is reached by similarity of the chosen materials default material settings (change of properties is done only the map changes (for example diffuse-, normal - and specular - map, etc.);

- Moving parts of the object are presented as individual objects (each object has its point of support and the direction of the axis of rotation corresponding to a simulated prototype (for example: the rotation centre of the wheel in its centre not on the side). The name of the textures, meshes, objects manufactured is made according to their purpose (for example, "axis" is an axis of a wheel, "wheel" – a wheel etc.). Assigning smoothing groups is made in accordance with the visual appearance of the prototype.).

Development of a 3D model is transferred to the customer in the Autodesk FBX format no lower than 2009. The model is placed in the centre of the scene, which does not contain foreign objects or materials. The customer is also get the render of the 3D model from the clearest point of view with the most characteristics.

The necessary input data includes:

- Information about the object and its purpose;

- Drawings of the object with all of the necessary sizes;

- Photos, drawings, sketches of object, and also the customer view of what it has to look like.

News

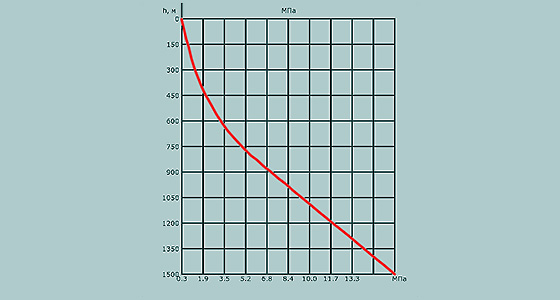

CML SPBGU Company developed new mathematical model of well-layer-pump system

This model allows prediction of local and integrated characteristics of a sheeted system under various conditions of impact on it, and to find the optimal operating conditions of the fields.

Have a question?

You need to get advice or to learn more about our capabilities?

Call us:

+7 (812) 716-18-16 and our manager will connect with you.