CML SPBGU Company develops a New Imitating Model for the LNG Tanker Processes

Published at November 5, 2013

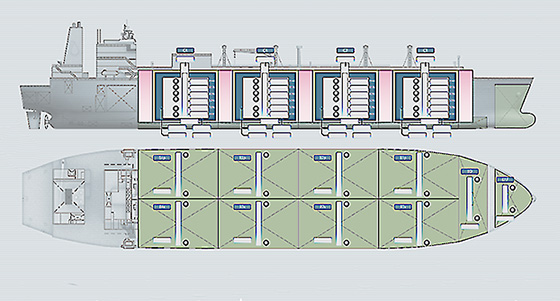

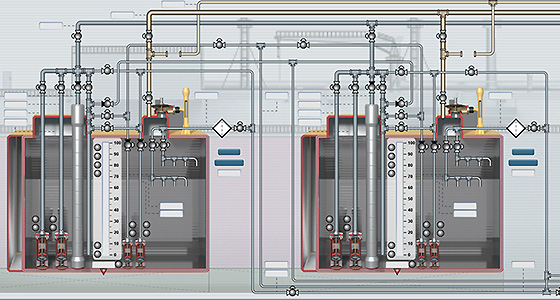

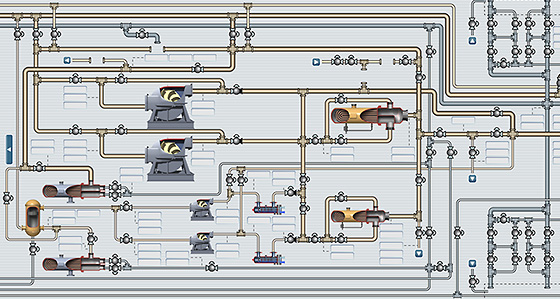

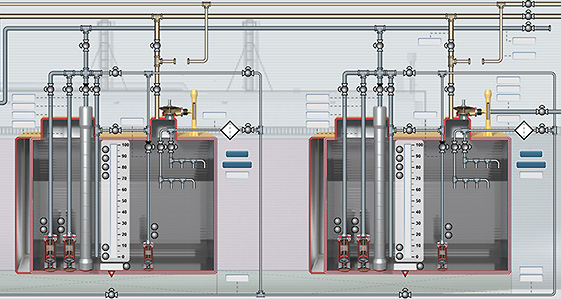

CML SPBGU developed new imitating model simulating the processes in pipelines and tanks of the Russian LNG tanker. The developed imitating model allows to display information data in real time getting from "ship sensors". The model is taking into account the external conditions changes and the wide range of parameters of system such as service parameters, emergency and post-emergency parameters of system.

Our imitating model simulated the following processes:

- Ballast operations (change the list and trim of the vessel, the condition before dry dock (all of ballast tanks are empty));

- Replacement method of cargo by inert gases in the tanks. The tanks can have parallel connection;

- Draining cargo tanks and systems by vapors of methane (GNG+) from the shore with the use of the shore gas connection;

- Cooling cargo tanks (GNG-) by pumping liquid methane from the terminal;

- Loading of the liquid methane (LNG) from the terminal;

- Keeping the temperature range in the cargo tanks during ballast passage;

- Unloading of methane (LNG) on the terminal and filling of space over the cargo with the vapors (GNG);

- Keeping the temperature range in the cargo tanks of the vapor (GNG) and liquid during sea passage;

- Heating cargo tanks (GNG+) (before decontamination and replacement of the gas environment by inert gas);

- Methane (GNG+) vapor replacement by inert gas (decontamination of cargo tanks);

- Cargo tanks and systems ventilation (O2+) before opening (or docking).

The simulation model allows generation of the data necessary to test the operation of the control stations. The model allows simulation of all the data with the real geometrical dimensions of the pipeline network, cargo systems heat exchanges of the LNG tanker. It also can simulate different conditions of operation and various emergency situations.

News

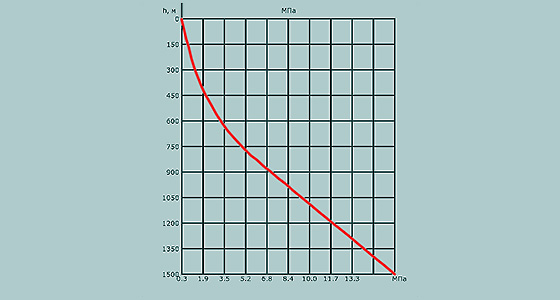

CML SPBGU Company developed new mathematical model of well-layer-pump system

This model allows prediction of local and integrated characteristics of a sheeted system under various conditions of impact on it, and to find the optimal operating conditions of the fields.

Have a question?

You need to get advice or to learn more about our capabilities?

Call us:

+7 (812) 716-18-16 and our manager will connect with you.